chrome bars

ENTER

Chrome Plated Tubes

ENTER

Cylinder Tubes

ENTERSPECIAL PROCESSES

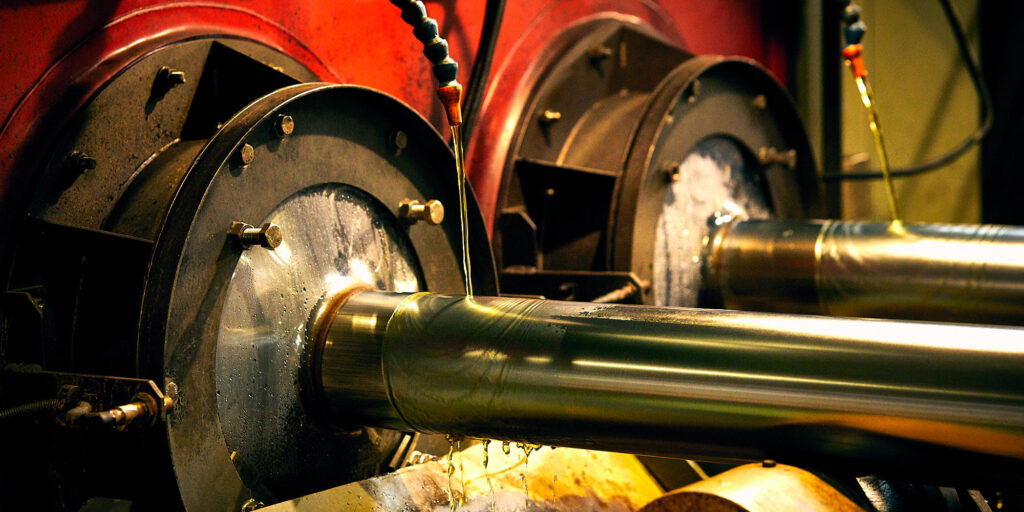

Mandrel bars reconditioning:

A strategic component in the production of seamless pipes is the mandrel bar, which works in contact with the incandescent blanks inside the rolling cages.

This process, repeated hundreds of times, compromises the chromium plating and often also part of the surface. As a result, what is known as “Elg Chromium Plating Reconditioning’” is required. This consists in downgrading to a lower gauge, bringing the spindle back to an as-new condition and giving it a new life.

SYSTEMS

The long history of Elg Chromium Plating Srl has been characterised by the presence of an in-house engineering department capable of designing and building complete continuous chromium-plating lines and the entire range of accessory machines:

- Single and multi-axis continuous chrome plating lines for diameters up to Ø 500 mm and lengths reaching over 20 metres.

- Special belt grinding for diameters up to Ø 500 mm and for lengths up to 20 metres.

- Chrome-stripping systems.

In this technology, which is already the subject of multiple patents, enabling:

- Better energy performance

- Improved product quality

- Even application

- Lower production costs and simplified automation

- Complete environmental safety

- Capacity to handle large diameters and indefinite lengths

- Low running and maintenance costs.

ITALY-ABROAD REALIZATIONS

Realizzazioni Italia-Estero

Diametro (in mm): 150 – 435